by Bauke Janssens | Published on 06 July 2023

high end ladle range

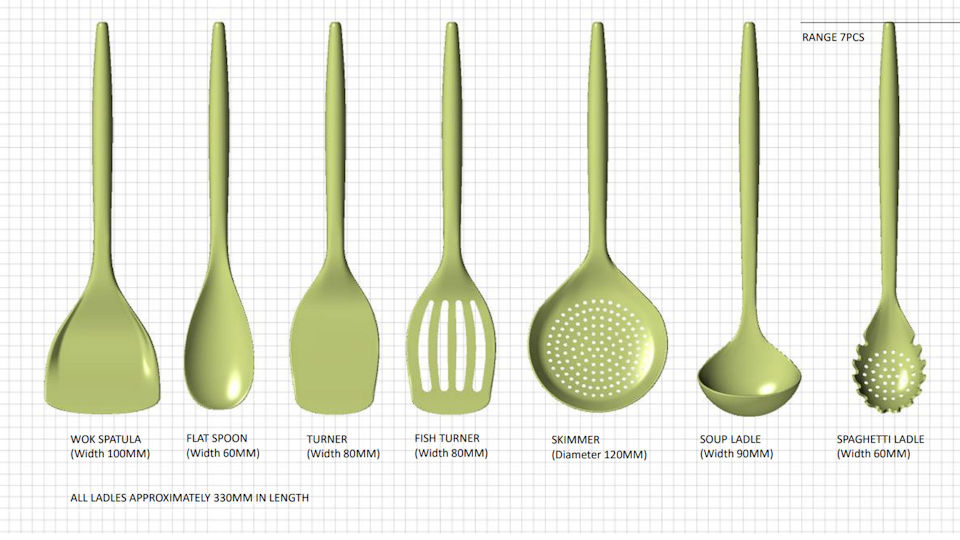

A local Hong Kong client (Win Win Metal) contacted us for the design of a new high-end ladle range which consisted of eight pieces in total, made out of wood, plastic and metal. Usually, as well for this client, we start with a client-briefing to get a good understanding of the request and requirements in more detail, get some design directions if any, and of course the timeline and budget for the project. Study ladle designs

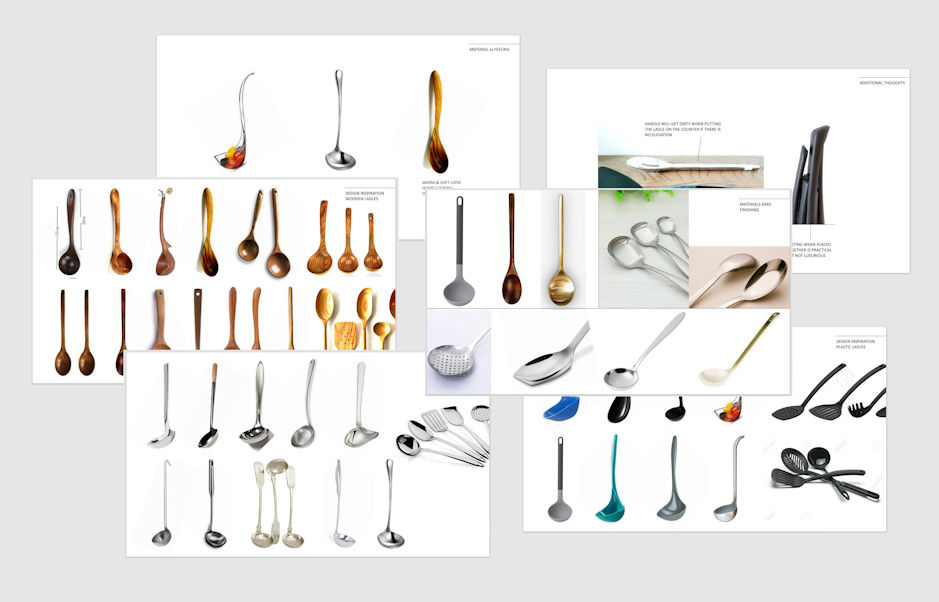

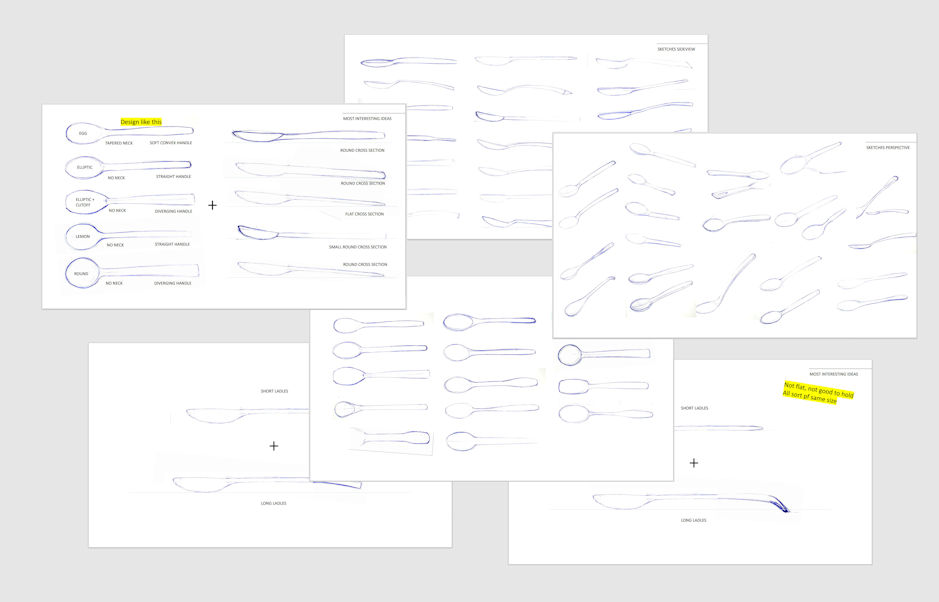

As we were quite new to this type of products, we started with a short study into current ladles on the market, to get a sense regarding shapes, styles and finishings etc. This study helped us to get a good understanding regarding what to consider for the uniqueness and personality in each ladle range. We considered this during creation of different ideas that we discussed with client and created a few initial renders of various ideas to discuss with client as well.

Work Out ladle Range

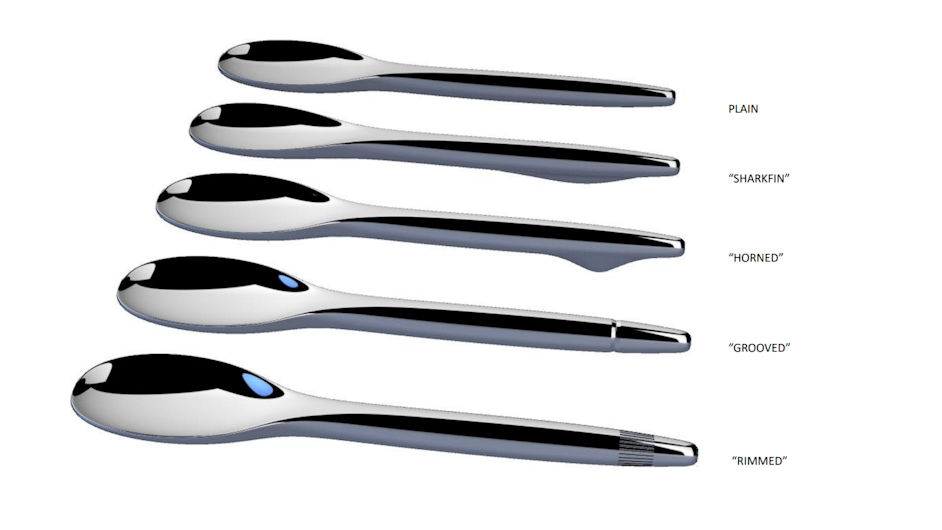

After discussing the ideas with client we agreed to work out a design with an egg-shaped bowl, a tapered neck and a soft convex handle and build our ladle range around that. After having created the draft design in our CAD software, including all the above mentioned features, we further worked out the design of the handle which we believed could be more interesting, making it stand out more from other ladles on the market. We created five variations for the handle-end, choose one to use and worked out all the complete ladle ranges. Deliverables: CAD-files, presentation material and a small presentation of the process.Follow Up

Client has put the design into production with here and there some modifications (especially for the wood variant, which needed to be made in much thicker material) but overall very similar to the design we created. For more information, contact Win Win Metal, Hong Kong.